Introduction to CNC Turning Technology

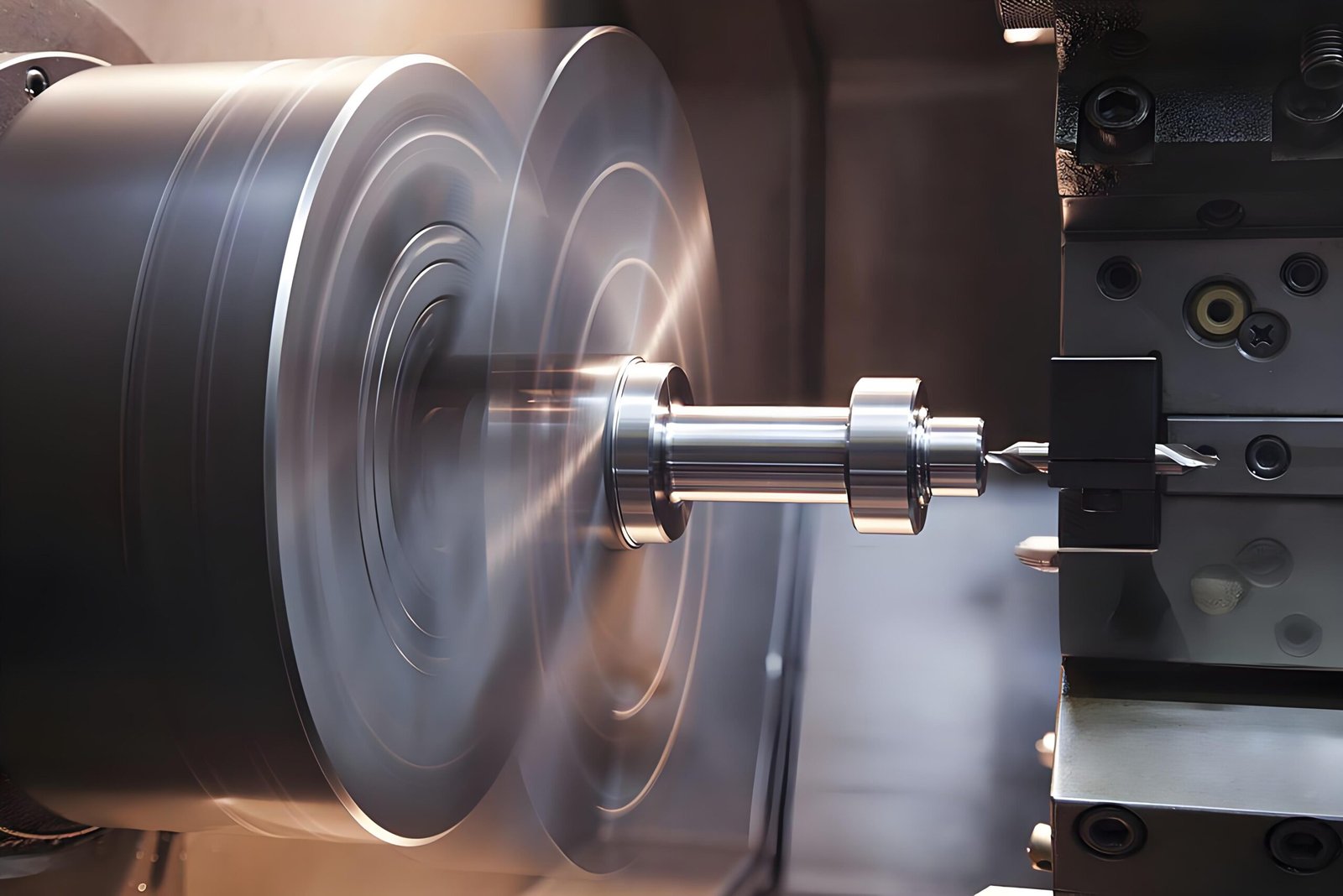

CNC turning (known as “toczenie CNC” in Polish) represents a revolutionary advancement in modern manufacturing. This computer-controlled machining process transforms raw materials into precisely crafted cylindrical components with exceptional accuracy. Unlike conventional manual lathes, CNC turning machines operate with minimal human intervention, delivering consistent results across production runs.

At its core, CNC turning involves rotating a workpiece while stationary cutting tools remove material to achieve the desired shape. The “CNC” in CNC turning stands for Computer Numerical Control, highlighting the automated nature of this advanced manufacturing technique.

How CNC Turning Works: The Precision Process

The CNC turning process follows a meticulous sequence:

- Material Preparation: Rod-shaped stock gets securely clamped in the machine’s chuck

- Tool Selection: Appropriate cutting tools are chosen based on material and design requirements

- Programming: CAD/CAM software converts 3D models into machine instructions (G-code)

- Machining: The lathe executes programmed commands with micron-level precision

- Finishing: Optional post-processing (like sandblasting) enhances surface quality

Modern CNC turning centers often feature live tooling capabilities, enabling additional operations like drilling, milling, and threading without removing the workpiece. This multifunctionality significantly reduces production time while improving accuracy.

Types of CNC Turning Operations

CNC turning encompasses several specialized techniques:

- Straight Turning: Produces uniform diameters along the workpiece length (ideal for shafts and pins)

- Taper Turning: Creates conical surfaces by adjusting tool angles

- Contour Turning: Follows complex profiles using programmed tool paths

- Facing: Flattens workpiece ends perpendicular to the rotation axis

- Grooving: Cuts narrow channels of specific widths and depths

- Threading: Forms precise internal or external screw threads

- Parting/Cutoff: Separates finished parts from the raw material

CNC Lathe Varieties for Different Applications

Manufacturers utilize various CNC lathe configurations:

By Orientation:

- Horizontal Lathes: Dominant in heavy industry for long shaft production

- Vertical Lathes: Excel at machining large-diameter components

By Complexity:

- 2-Axis Machines: Basic turning operations

- Multi-Axis Centers: Combine turning with milling (Y-axis) and secondary spindles

- Swiss-Type Lathes: Specialized for small, intricate parts with guide bushings

By Production Volume:

- Single-Spindle Lathes: Versatile for prototyping and small batches

- Multi-Spindle Lathes: Mass production specialists with simultaneous machining

Material Considerations for CNC Turning

CNC turning accommodates an extensive material range:

Metals & Alloys:

- Aluminum (lightweight, corrosion-resistant)

- Stainless Steel (durable, heat-resistant)

- Brass/Bronze (excellent machinability)

- Titanium (high strength-to-weight ratio)

Plastics:

- POM/Delrin (dimensional stability)

- Nylon (wear resistance)

- PTFE (chemical resistance)

Advanced Materials:

- Inconel (extreme environments)

- Carbon Fiber (high-performance applications)

Material selection directly impacts machining parameters like cutting speed, feed rate, and tooling requirements.

The Competitive Advantages of CNC Turning

- Unmatched Precision: Achieves tolerances within ±0.005mm (±0.0002″)

- Rapid Production: Delivers prototypes within 24 hours in many cases

- Cost Efficiency: Reduces material waste through optimized cutting paths

- Surface Quality: Produces finishes down to Ra 0.8μm (32μin) without polishing

- Complex Geometries: Machines intricate features impossible with manual methods

- Repeatability: Ensures identical parts across production runs

Industry Applications of CNC Turning

Automotive Sector:

- Engine components (valve stems, pistons)

- Transmission parts (gears, shafts)

- Suspension elements (bushings, joints)

Aerospace Industry:

- Turbine blades

- Landing gear components

- Hydraulic system parts

Medical Field:

- Orthopedic implants

- Surgical instrument parts

- Dental prosthetics

Electronics Manufacturing:

- Connector pins

- Heat sink components

- Enclosure parts

The CNC Turning Workflow: From Design to Delivery

- Design Phase: Engineers create 3D CAD models with manufacturing considerations

- Programming: CAM software generates optimized toolpaths

- Setup: Technicians install proper tooling and workholding

- Machining: Automated production with real-time monitoring

- Inspection: Quality verification using CMMs and other metrology tools

- Post-Processing: Secondary operations (deburring, plating, etc.)

- Delivery: Fast shipping options for time-sensitive projects

Why Choose CNC Turning for Your Project?

CNC turning offers distinct benefits compared to alternative manufacturing methods:

- Faster turnaround than traditional machining

- Lower per-unit costs for medium production runs

- Greater design flexibility with quick program modifications

- Superior consistency compared to manual operations

- Material versatility across metals, plastics, and composites

For manufacturers seeking rapid prototyping or production parts, CNC turning provides an optimal balance of speed, precision, and cost-effectiveness. Many service providers offer instant online quoting by simply uploading CAD files, with production times as short as one day for standard components.

Conclusion: The Future of Precision Turning

As manufacturing technology advances, CNC turning continues evolving with smarter automation, improved tooling materials, and enhanced software capabilities. The integration of IoT sensors and AI-driven process optimization promises even greater efficiencies in the coming years.

For businesses requiring high-quality turned parts, understanding CNC turning capabilities ensures optimal design decisions and production outcomes. Whether producing simple bushings or complex multi-feature components, modern CNC turning delivers precision results with remarkable consistency and speed.